|

|

|

Greenwood

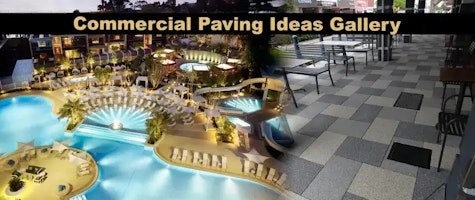

Outdoor display & stock centreOur biggest display with over 900m2 of new paving & cladding ideas. "A must visit" before selecting your outdoor flooring.

Hours

Phone: (08) 9247 1600 |

|

Bibra Lake

Manufacturing facility, full scale display & stock centre

Hours

Phone: (08) 9418 8404 |

CONTACT US NOW

Email us at info@freostone.com.au or fill out the form below:

We have noticed that your browser doesn't have Javascript enabled. Our form system requires it to be enabled. Please click here for instructions on how to enable Javascript.

YOUR FEEDBACK MATTERS

Freo Stone Paving is owned by local Perth families who have built the brand on service, quality and innovation. 90% of our clients are referred to us by past clients. If you have feedback on what we have executed well, or what we can do better, we are listening...

Email Managing Director, Scott Pedretti below:

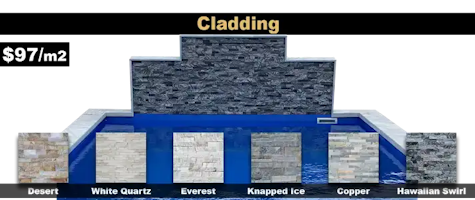

Paving Perth

and Australia for nearly two decades. Freo Stone Paving boasts an evolving range of quality pavers, now including limestone pavers, travertine pavers, porcelain pavers, exposed aggregate pavers and Stormstone bluestone pavers. Also a stunning range of durable natural stone feature wall cladding. Perth project owners, paving contractors and landscape design professionals are constantly working together with the Freo Stone Paving team to create functional, yet attractive paving ideas for residential and commercial paving. Our team spend all day, every day providing landscaping design ideas to compliment building projects large and small. Our huge Perth outdoor paving ideas display centres are located in Greenwood and Bibra Lake. Both sites offer design and product advice from experienced projects designers and ex-installers. In addition to the various full scale concepts built on the sites, there is also a huge amount of stock on hand for you to peruse, order or purchase on the spot. Our Bibra Lake production facility utilises the highest technology available for professional mixing, machining and production of paving products. Eight robots carry out accurate and consistent manufacturing and quality control processes to assist in delivering a high standard finish in an efficient manner, to help your project planning and execution flow as easy as possible.

Freo Stone's poured limestone and aggregate paving provide a trusted premium quality option, far more attractive and flexible than site poured products. Combined with sweep in and wet to set grouting products, selecting pavers will provide you with a low maintenance, yet natural, individual and attractive project finish. Our pavers also offer the flexibility of removal and reinstallation after the various fence post, electrical or plumbing installations or repairs present themselves. No cutting, cracking or breaking like site poured concrete. Freo Stone Paving manufactures pavers in Perth, offering a cooler alternative than most paving options due to our focus on producing attractive colours with the best thermal qualities possible. Darker colours always attract more heat under your feet and for most areas in Australia, this needs to be considered when designing your landscape project to not only be beautiful, but functional. Freo Stone Paving offer paving solutions to improve or create any landscape project so be sure to speak with our team about what you are trying to achieve and they will ask all the questions regarding components you may not have thought of already. Our team possess a wealth of knowledge from experience and being on the front line of design, product and project developments day to day. The most attractive side of this for our customers is that it is FREE, so utilise the service we offer to help you on your way to a Rock Solid Investment you will be happy with for many years to come. For your convenience we frequently also offer options complimentary to paving including matching stylish stone pool skimmer box covers (far more attractive than traditional plastic lids), artificial turf, adhesives, stone wall cladding and more...

Freo Stone Paving is a trusted Perth paving supplier but can also assist with Perth paving services from individual paving contractors to complete commercial landscaping designers and installers. Speak with our experienced team to direct you to some of the many local companies our clients have achieved great success with. Limestone Paving, Travertine Paving, Porcelain Paving, Stormstone Bluestone Paving, Timber-look StoneDek Paving and Natural Stone Feature Wall Cladding are all fantastic options to separate your project from the norm. As the bulk of our clients are repeat installers, builders or landscape construction professionals, we are sure we can refer you to knowledgeable and meticulous individuals and companies even outside of the paving scope of works.

TIPS SUMMARY

Read your delivery date email and save the date to phone calendar .

Leave stone for installer to cart into site as and when needed.

Leave work area free and clean until completion to avoid damage or delay.

Never use sand for join filling.

Use a "wet to set" join powder/gel.

Engineered pavers – do not leave pallets unwrapped and do not stack pavers – permanent hydration stains may occur.

Only seal if required and use only the products recommended in the table overpage to avoid damage.

Sealing is for experienced professionals and DIY is not recommended.

TIPS IN MORE DETAIL

DELIVERY TO SITE

Once your payment is processed our scheduling team will produce or prepare your pallets and allocate a delivery date. This date will be emailed to you on your final receipt and can only be changed with 7 days noticed to avoid double charges by freighters who have committed drivers income to that booking. Your site is best loaded than not, as a rule. We are unable to advise what time of day between 7am & 7pm for delivery or contact freighters when driving. Please set a reminder in your phone calendar to ensure your site verge remains clear for set down of the number of pallets on your invoice. Pallet space required is 1.2m x 1m per pallet or crate. Then await arrival of installers to use their experience to cart the stone in a safe manner as needed to avoid chipping, damages or placement in the way of their work process.

Engineered wet cast pavers should remain wrapped on their pallets until they are ready to be installed. This is because they finish their drying process once placed on the ground. Moving pavers directly from the pallet to the installation site at the time of install helps prevent hydration staining and uneven expansion/contraction, which can lead to surface fractures. Avoid stacking pavers for prolonged periods, as this can cause these issues. Note that small surface lines may appear during curing, but these are not structural concerns.

DURING INSTALLATION

Whilst half finished works may look safe enough to walk on or touch, you may actually damage the installers alignment, levelling, fixing or grouting process. Please leave the work area free from foot traffic, mats, carpets, steel, water or any items which may rust, damage, stain or upset the products or workmanship. Only on completion and curing confirmation from the installer can the project be accessed, admired and enjoyed. Like anything, prevention is better than a cure.

STONE JOIN FINISHING

Next to concrete restraining of loose edges, join filling is one of the most important components of any paving project. Filling joins (the gaps between the stones) provides long term durability of your floorspace and help hold the paving firmly in place. Joins are never for drainage, all paving should be installed with a fall to ensure water runs away to various drainage points and is never allowed to puddle on the stone.

Yellow or "washed" white sand is never to be used for join filling. Besides holding unwanted moisture around the edges of stones when wet, these sands can allow seeds to land and grow into weeds. These seeds often travel in the breeze and can shoot down roots in any sand. Most weeds do not actually begin under the paving and despite myths about placing materials under the paving to reduce weeds, the joins on the surface are actually where the issue can be.

Washed white sand may look good on the first day but it is all down hill from there. Do not use it, there is an alternative. At a similar cost to troublesome sand, bagged join powders are a far superior solution that actually expand and set firmer than sand once wet and set. Weeds struggle to anchor to these fillers, moisture runs over them and pavers can still be removed and replaced as needed for future works or additions of pipes, wiring or fences. These powders work very well when installed correctly and maintained by topping up any joins that require it post heavy cleaning or modification works for example.

These powders simply sweep in and are vibrated deep into the joins using a carpet under a compactor or other means. Then a final neat sweep in (leaving no powder on the surface) and misting from above with water a few times over 30 minutes will set the fill powder to a gel or biscuit like firm join. Not all join grout powders perform well over time. The most popular and successful join grout powder with our stone is listed below as an example.

PAVE SET by Adbri (available at Freo Stone Paving and used successfully in all of our displays). PAVE-LOK is another.

SEALING IF REQUIRED

Many sealers can actually damage stone. Seal only if required using Freo Stone Paving Approved Sealers.

The stone itself is durable and sealing does not make it any more so. Sealing may simply make some mess easier to clean.

The sand, leaves, food or other items will still land on the surface and make it dirty, but a sealer may make it easier to remove. Sealing is about the environment the stone is in, not the stone itself. The same stone may be subjected to no mess at one site and many messy factors at another. Some choose to see what their stone is subjected too for a while first and then engage a cleaning and sealing professional if needed. Some are aware the area will be subject to mess and will seal from the start.

No Sealer is better than the wrong sealer. We can help with dirty paver solutions. We can't help damage from the wrong sealer. Below we offer a guide developed through years of experience and feedback with our stones. A guide we follow for our own sites and homes.

|

Paver Type |

Standard Finish (Natural to light sheen) |

Enhanced Finish (Darkened to wet look) |

|

Ice Sandstone Greystone Charcoal |

Bondall Paving & Concrete Sealer Matt Finish Available @ Freo Stone Paving |

CCS Stain Block - ONLY DRIVEWAY PAVERS Available @ CC&S 0404447299 |

|

Spirit Seal Natural Paving Sealant Available @ PC Coatings 0419 951 657 |

CCS Stainblock - ONLY DRIVEWAY PAVERS Available @ PC Coatings 0419 951 657 |

|

|

CCS Streetscape Available @ CC&S 0404447299 |

||

|

Abrolhos Metro |

Bondall Paving & Concrete Sealer Matt Finish Available @ Freo Stone Paving |

CCS Hi-Build Available @ CC&S 0404447299 |

|

CCS Streetscape Available @ CC&S 0404447299 |

CCS Stainblock Available @ PC Coatings 0419 951 657 |

|

|

Q-Coat Water-Based Available @ PC Coatings 0419 951 657 |

||

|

Ocean Bluestone |

CCS Streetscape Available @ CC&S 0404447299 |

CCS Stain Block Available @ CC&S 0404447299 |

|

Spirit Seal Natural Paving Sealant Available @ PC Coatings 0419 951 657 |

CCS Stainblock Available @ PC Coatings 0419 951 657 |

|

|

Travertine & Marble |

DO NOT SEAL |

|

|

DesignoPave - StoneDek |

DO NOT SEAL |

|

Further technical sealer information is available @ www.bondall.com.au and www.concretecoloursystems.com.au

We highly recommend any sealing required be undertaken by an experienced professional. Inexperience can ruin your valuable investment in many ways.

Application of the wrong sealer (there are many) can actually damage your stone long term to an irreversible state. Use only what we have recommended, not "all purpose" sealers regardless of what packaging says they are for.

The wrong sealer or over application of any sealer can result in a very slippery surface.

Any invisible moisture or visible micro debris will be trapped under any sealer if the area is not prepared correctly. Paint preparation and application methods vary from stone to stone and project to project.

Sealing really is not for the DIY list. Use an experienced professional to be safe.

GENERAL CARE

High Pressure Water. Any cleaning is best completed dry first with a broom, then spot cleaning any stains. As tempting as high pressure cleaning may be, focus the spray (at a distance of 30cm on wide spray as a guide for most pressures) only at the stone face itself, not joins. Refrain from blowing out any join powder gel as you will need to reapply it.

As a rule, cleaning professionals use light detergents first moving up in strength if required depending on the stain.

Acid is not to be used freely and may eat or etch your stone or joins in most instances, regardless of how diluted.

Prevention focus. If for any reason your projects edge restraints or joins show any signs of movement or cracking over time, ensure they are solidified or filled again immediately. If there is any room for stone to move, the surrounding stones may follow and spread creating weak points.